|

A world-wide-web site

which comprehends A world-wide-web site

which comprehends

spirituality in a modern context in review of

ancient teachings

and religious belief-systems.

|

|

W e l c o m e T o S c

i e n c e L i n k s S i t e s)_9

Interaction Of The Universe To The

Individual

P R O M O T I N

G C O N S C I O U S N E S S O

N T H E I N T E R N E

T

|

SOLAR POWER |

Standard Solar

Power Modules and Arrays

|

Make This WebPage instantly

available in other languages

|

Become

Energy

Independent

We offer a range of complete solar power systems for homes connected to

the electric utility grid. Now almost any home can generate its own

electricity with a complete GE solar electric home power system. Engineered

to install quickly and reliably to provide years of automatic operation, our

residential solar electric systems include everything you need in one

complete package.

Features and Benefits

Available with or without an uninterruptible power

supply, our pre-packaged systems make solar electric home power more

convenient than ever. The residential system includes everything you need to

make your own electricity. Designed to provide years of automatic operation,

our systems come complete with solar modules, plug-and-play wiring, power

electronics, patented mounting kits for roof or ground mounting, a power

meter to monitor performance and complete documentation for contractors and

homeowners. GE solar systems are currently available only in the United

States. Please contact us at 800-310-7271or 201-755-6170for further

information. Also, please read our frequently asked questions for

residential systems and small commercial systems up to 10 KW.

For new

home builders, Aten Solar works with the builders and

contractors in order for the solar system to be easily integrated into

current building plans. The program provides builders with access to

experienced, knowledgeable professionals who can provide hands-on assistance

with training, permitting, installations, inspections and warranty support.

Builders who use Aten Solar have access to the only complete, pre-engineered

packaged solar power system on the market today. This fully integrated

system gives homebuyers a unique value added feature, a complete packaged

system designed and tested for system wide reliability and durability before

installation.

Pre-packaged Systems

- Solar

modules are

hail-resistant and produce 100 watts DC power in full

sunlight

- Solar

array

sizes

available from 12 to 96

modules

- Systems

generate

1,200 to 9,600 watts of solar

power in full

sunlight

- Pre-engineered rooftop mounting systems withstand up to 125 mph

wind (50

lbs/ft²)

- High

reliability

DC-AC inverter continuously

converts solar DC current into common household AC current

- Easily mounts above curved and flat tiles and asphalt

shingles

|

Make This WebPage instantly

available in other languages

|

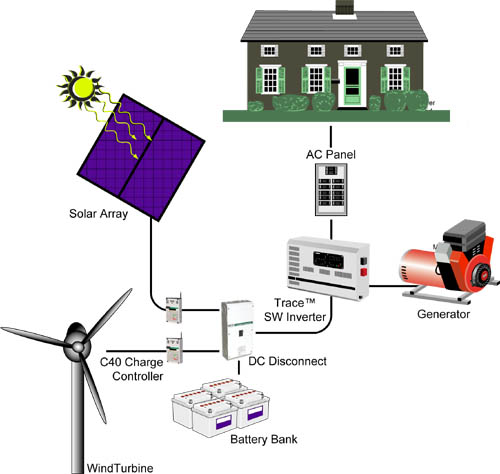

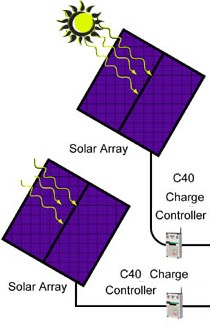

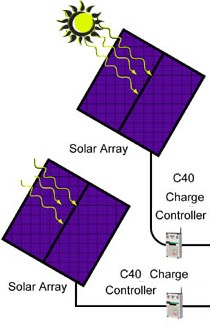

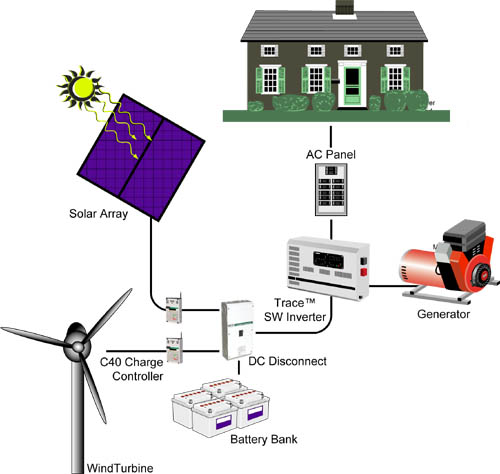

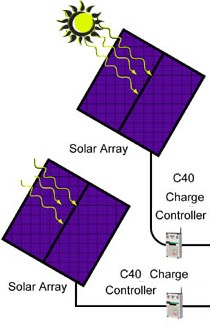

System

Diagram

Off

Grid System Components:

For a functional

description scroll down to read about the

individual System Components.

|

Off Grid System

Components |

Electric Panel:

A distribution terminal for

electric wiring (also called a circuit breaker panel or breaker box). All the

wiring in a home or office terminates at a main electric panel and is supplied

with electricity from the inverter.

Engine Powered Generator:

Uses an engine to generate

electricity, typically from natural gas, propane, or diesel fuel. Unlike

batteries, which store only a fixed amount of energy, a generator can produce

electricity for as long as it is supplied with fuel. A high-quality generator

can be fairly quiet, but never noise-free. Like all engines, generators require

periodic maintenance.

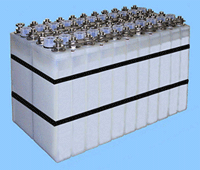

Battery Bank:

Stores energy for use on

demand. In an Off Grid electrical system the battery bank provides the reservoir

of energy available to power loads. The size of the battery bank determines how

long power will be available before battery recharging becomes necessary. The

power rating of the inverter determines how many appliances you can use at any

one time. The power rating of the battery charger determines how quickly your

battery bank can be recharged by a generator or other outside AC source.

There are a number of types of deep cycle batteries available which are

suitable for inverter operation. Some of them are sealed and require virtually

no maintenance.

Solar Electric Panels:

Convert sunlight

directly into electricity used to charge storage batteries. One of the most

reliable means to generate your own electricity, solar panels can generate power

for decades and require little maintenance. Solar electric generating systems

may be sized to provide ample power for most typical residential and commercial

power requirements.

Inverter/charger:

Converts the DC power stored

in batteries to regular household current. Xantrex inverters, which consistently

provide better-than-utility power, make the use of solar power practical. Trace™

inverters have an efficiency rating as high as 96%, are noise-free, and function

as the brains of your fully automatic off grid electric system.

Most have

built-in battery chargers which are designed to be used with generators to

quickly recharge batteries when solar power is not sufficient.

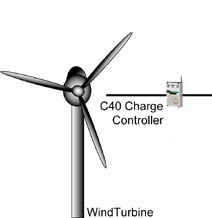

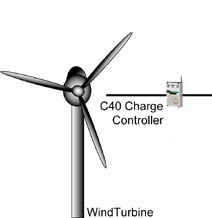

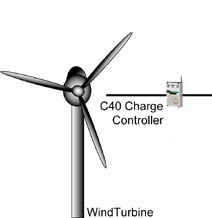

Charge Controllers:

A charge controller is a

device used to control the amount of power generated from a PV array, wind

turbine, etc., to a battery. It is used to protect the batteries from harmful

overcharge conditions.

DC Disconnect:

A DC disconnect is almost

identical to the AC circuit breaker found in your home. It is designed to

protect DC circuits (batteries, PV arrays, etc) from short circuits or overload

conditions.

Wind Turbine:

A wind turbine generates

electrical current as its blade spins. The faster the blade spins the more

electricity is generated. Residential scale wind turbines produce between 400

and 10,000 watts of power.

I m p o r t a n t S

t u f f

I m p o r t a n t S

t u f f

EFFICIENCY

The best first step toward renewable energy is to make sure your

home is energy and water efficient. And, there are new federal tax credits to

help you!

INSTALLING A RENEWABLE ENERGY

SYSTEM

Finding a qualified contractor is an important first step. Here are other

steps in the process you should understand, so you can work intelligently with

your contractor:

Usually your contractor or installer will handle much of

the paperwork for you. But you will need to sign forms and manage some of the

steps yourself. We've outlined the main steps here for you.

LEARN ABOUT FINANCING YOUR

SYSTEM

Rebates, tax credits and other financial incentives are available today.

These can significantly reduce the price of installing a renewable energy

system. Also learn about property tax, leases, power purchase agreements and

more ...

GREEN TAGS

Are a versatile new way for consumers and businesses to participate in the

national transition to renewable energy. Green tags make it possible to support

renewable energy regardless of whether your state is deregulating its energy

markets. In some markets and situations Green Tags can be sold or traded. Check

with a Solar Pro to see what might be available to you.

|

Make This WebPage

instantly available in other

languages

|

|

Configurations

From One Appliance to an Entire Business

All solar electric systems

use solar cells, encapsulated in weatherproof modules, to convert free

sunlight into DC electricity instantly. How the modules are connected

and what happens to the electricity depends on the particular type of

application. Several typical system configurations are described

below.

|

Directly Connected

Systems

Solar Module(s) Connected Directly to a DC

Motor Load

Components: Solar modules and mounting

hardware, DC motor or pump and disconnect switch or circuit

breaker.

How it works: The solar module produces DC current that is used

immediately by a motor. As sunlight rises and falls, current and voltage

rise and fall, and the motor speeds up and slows down proportionally.

There is no power storage. The motor operates slowly during cloudy or

stormy weather and does not operate at

night.

Applications: Remote

water pumping, a ceiling or attic fan or a solar thermal (hot water)

circulation pump

Small Solar Module Connected to a Large

Battery

Components: Solar module, fuse and/or fused disconnect

switch

How it works: A small current flows from the solar module through a

starting battery to counteract any inherent self-discharge in the battery.

A trickle charge flows only during daylight hours, but on average offsets

any self-discharge.

Applications: Trickle charging of vehicle starting batteries (fleet vehicles,

seasonal road equipment like snowplows) and boat

batteries

Stand-Alone Systems

Solar Modules Connected Through a Charge

Regulator to Battery Storage

Components: Solar modules and mounting hardware, a charge

regulator, storage batteries and disconnect switches or circuit

breakers

How it works: A solar array produces DC current that passes through the

charge controller into storage batteries. The charge regulator reduces or

stops charging current to prevent battery overcharge. Small DC loads may be

connected to the charge regulator, which can then prevent battery

over-discharge. The battery operates loads at night and during overcast or

stormy days. Solar modules recharge the batteries when average or good

weather returns.

Applications: Remote

industrial areas (telecommunications, navigational aids, cathodic protection and

traffic systems) and remote home systems

Above System with DC-AC Inverter Connected

to Battery

Components: Above components with the addition of an

inverter and an AC distribution center

How it works: Same as above with the addition of an inverter to operate AC

loads. The inverter draws power from the battery and changes DC to AC

current and voltage. For safety, power is sent to the distribution center

which houses circuit breakers for individual AC circuits. The inverter

operates from battery energy day or night.

Applications: Remote

home systems

Above System with

Generator

Components: Above components with the addition of a fuel

generator (gasoline, diesel or propane), a rectifier and a sophisticated

hybrid system controller

How it works: The system controller monitors the battery voltage. When the

voltage drops to a safe but low level, the generator is turned on. AC output

is converted to DC power and recharges the battery. AC output can also be

used directly to power AC loads. When the battery reaches an almost full

recharge level, the generator is turned off. The solar array can be sized to

supply average GE needs throughout the year, and the generator is used to

fill in during seasonal low output periods and prolonged bad

weather.

Applications: Village power systems

Grid-Connected

Systems

Solar Modules Connected to a Utility

Interactive Type Inverter

and Utility Power Grid

Components: Solar modules and mounting hardware,

disconnect switches or circuit breakers and a grid interactive

inverter

How it works: The solar array produces DC current that passes through

inverter, which converts to AC current and voltage. Power is sent to the

utility meter and is either consumed immediately by home or business loads,

or is sent out to the general utility grid network. The utility meter spins

backwards, or two meters are used to record incoming and outgoing power. At

night, loads operate from utility power since the solar power system does

not produce power. The inverter shuts down automatically in case of utility

power failure for safety, and reconnects automatically when utility power

resumes.

Applications: Urban residential and commercial systems and utility-scale

power plants

Above System with a Bi-directional Inverter and Battery

Backup

Components: Above components with the addition of a

battery bank, charge regulator and bi-directional inverter.

How it works: The solar array charges the battery bank through a charge

regulator. DC power from the battery passes through the inverter and is

converted to AC current and voltage. Power is sent to the utility meter and

is either consumed immediately by home or business loads, or is sent out to

the general utility grid network. The utility meter spins backwards, or two

meters are used to record incoming and outgoing power. At night, loads

operate and the battery bank is kept trickle charged from utility power

since the solar power system does not produce power. In case of utility

power failure, the direct connection to the utility meter is shut down for

safety. Selected circuits in the home or business that are connected to a

special secondary inverter output continue to operate, drawing energy from

battery bank. The solar array recharges the battery each day until normal

utility power resumes.

Applications:

Urban residential and commercial

systems

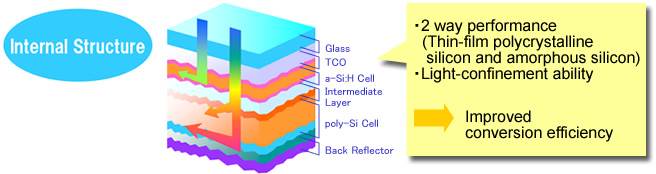

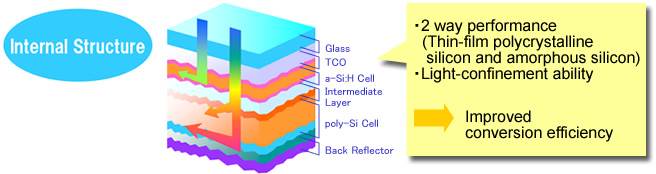

High Effective Hybrid PV

| |

Environmental

pollution and energy shortages are now of global concern. More interest is

focusing on photovoltaic (PV) power generation, which can use an unlimited

source of clean energy - the sun. Kaneka decided to begin research into

thin film silicon PV modules at an early stage. This has allowed the

company to assume a leading position in the industry over the past 20

years.

Kaneka's accumulated

expertise now makes it possible to offer next-generation energy all over

the world through its advanced PV systems that empower individuals to take

a proactive environmental role in their daily lives.

Crystalline-Si PV

modules lose some power-generating capability with rises in temperatures.

But Amorphous-Si PV modules have higher power generation capability during

extreme summer time. Amorphous-Si PV modules can deliver maximum

performance during summer afternoons. Therefore the amorphous-Si PV

systems can contribute during the time when the electricity is needed most

for air-conditioners in houses and offices.

*Kaneka Silicon PV's generated watt-power is

approximately same as that of other crystalline silicon PVs during the

winter months, but in summer the Kaneka Silicon PV generates significantly

more power compared to other crystalline silicon PVs.

Source:

"NEDO/Ritsumeikan University Demographic Module Field Test and Operational

Analysis" presented at the International PV SEC-11, Sapporo, Hokkaido,

Japan, 1999.

Installation location: Kusatsu, Shiga Prefecture Japan

Slope angle: 15.3 degree

|

|

*Kaneka Silicon PV's generated

watt-power is approximately same as that of other crystalline

silicon PVs during the winter months, but in summer the Kaneka

Silicon PV generates significantly more power compared to other

crystalline silicon PVs.

Source: "NEDO/Ritsumeikan University Module Field Test and

Operational Analysis" presented at the International PV SEC-11,

Sapporo, Hokkaido, Japan, 1999.

Installation location: Kusatsu, Shiga

Prefecture Japan Slope angle: 15.3

degree |

|

|

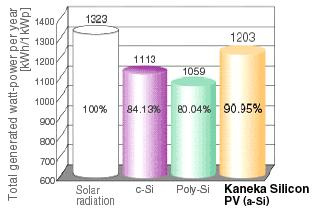

Kaneka's amorphous silicon (a-Si) has

superior light absorption per nominal watt power. Compared with

mono-crystalline (c-Si) or poly-crystalline (poly-Si), it generates

considerably more power per nominal watt power.

Assuming that the total solar radiation per

year (1.323kWh/m2) is 100%, Kaneka Silicon PV can produce 90.95% of

actually generated watt-power, much higher than that of other

crystalline |

silicon PVs (80 to 84%).

Source:

"NEDO/Ritsumeikan University Demographic Module Field Test and Operational

Analysis" presented at the International PV SEC-11, Sapporo, Hokkaido,

Japan, 1999. Installation location: Kusatsu, Shiga Prefecture Japan Slope

angle: 15.3 degree

*NEDO : New Energy and

Industrial Technology Development Organization

|

|

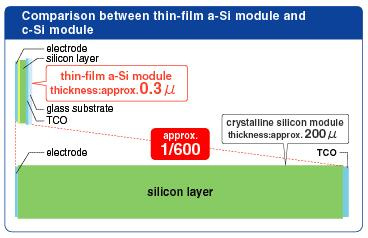

Another advantage is that the single junction

a-Si layer can be made extremely thin.

The thickness of a-Si cell

is 0.3, which is 1/600 of that of crystalline silicon

cell.

This uses less material and energy

thereby enabling high productivity for mass production (approx.

200).

|

|

|

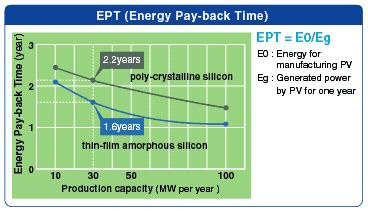

EPT is the time a PV module to "pay back" the

energy used in its manufacture by its own power generation.

The

EPT of amorphous-Si PV is 1.6 years, which is approximately 6 months

shorter than that of crystalline silicon PV (2.2 years).

EPT is one of the most important aspects when

evaluating the ecological benefit of PV

systems. |

Quality

·

IEC 61646 tested and certified

·

safety class II for 530 V system voltage (projected)

Guarantee

·

25 years power warranty (80%)*

·

12 years power warranty (90%)*

·

5 years product guarantee*

High

performance

·

power tolerance +10%… -5%

·

higher yield on plant due to higher power output on delivery

·

high yields even at high module temperatures

Ecological

advantage

·

Extremely low consumption on material -> energy payback time less than

2 years

Design

·

Homogeneous colouring of frame and module surface -> high-class,

harmonic appearance

|

Electrical

Characteristics |

Stabilised

values |

Initial

values |

|

Nominal peak power (Wp) |

60,0 |

79,0 |

|

Guaranteed minimum power (Wp) |

57,0 |

75,05 |

|

Nominal voltage (V) |

67,0 |

74,0 |

|

Nominal current (A) |

0,90 |

1,04 |

|

Open-circuit voltage (V) |

92,0 |

96,0 |

|

Short-circuit current (A) |

1,19 |

1,22 |

|

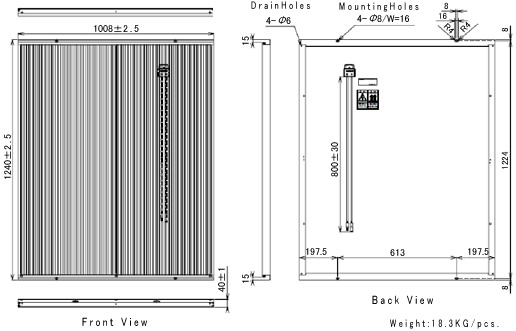

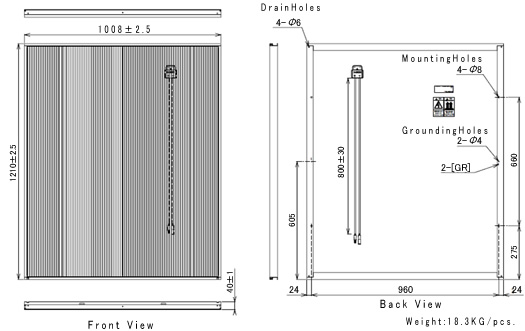

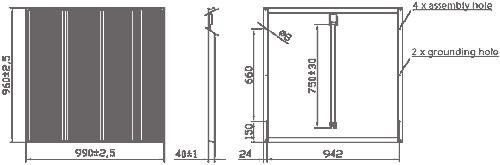

Physical

Characteristics |

|

Maximum system voltage (V) |

530 |

|

Length (mm) |

960 |

|

Width (mm) |

990 |

|

Height (mm) |

40 |

|

Weight (kg) |

14 |

|

Assembly holes ø 8 mm (pieces) |

4 |

Boxing dimensions:

1 crate = 44”W x 42” D x 44”H and

750 lbs.

There are 25 modules in a crate.

The crate is

separated into two compartments, one with 12 modules and one with 13

modules. Each module is separated from the others by a solid cardboard

separator sheet.

For price quotations on container shipments (1 x 20

FT container = 550 modules) or 1 x 40 FT container = 1100

modules)

Your

Price Qty 1 Total $9800.00 SKU 1.44KWKANTK

Product

Title 1.44KWTK

Kaneka Solar Prepackaged/Turnkey Grid Tie System

Image

Weight

(lbs) 915.00

Suggested

Products 1.8

KW GE Energy Brilliance Prepackaged/Turnkey Grid Tie

System

Your

Price Qty 1 Total $5625.00 SKU GSA-60

Product

Title 25

Kaneka Solar 60 Watt Modules Description:

60 Watt Amorphous

Silicon Solar Module-Sold as lot of 25

Image

Weight (lbs) 825.00

Your

Price Qty 1 Total $16889.00 SKU 3.0KWKANTK

Kaneka Solar Prepackaged/Turnkey Grid Tie System

Product

Title 3.0

KW Kaneka Solar Prepackaged/Turnkey Grid Tie System

Image

Weight

(lbs) 1725.00

Suggested

Products

1.44KWTK

Kaneka Solar Prepackaged/Turnkey Grid Tie System

1.8

KW GE Energy Brilliance Prepackaged/Turnkey Grid Tie System

25

Kaneka Solar 60 Watt Modules Description: 60 Watt Amorphous Silicon

Solar Module-Sold as lot of 25

|

|

Make This WebPage instantly available

in other languages

|

Pre-packaged

Systems

- Solar modules

are hail-resistant and produce 100 watts DC power

in full sunlight

- Solar array

sizes available from 12 to 96 modules

- Systems

generate 1,200 to 9,600

watts of solar power in

full sunlight

- Pre-engineered

rooftop mounting systems withstand up to 125 mph

wind (50 lbs/ft²)

- High

reliability DC-AC inverter continuously converts solar DC current into common household AC

current

- Easily

mounts above curved and flat tiles and asphalt

shingles

| |

|

|

|

|

|

|

|

|

|

|

|

| Grid Tie- 7.2 |

Grid Tie-7.4 |

Part |

Description |

|

|

|

|

|

|

|

|

| 36 |

37 |

GEPV-200M |

GE Energy 200 Watt Photovoltaic Module, Silver Frame, White

Back Sheet, 25 Year Warranty |

| 0 |

3 |

GE-2.5 Inverter |

GE

inverter-2500 watts, 240 Vac, 60Hz (Standard 10 Year Warranty) |

|

|

|

| 2 |

0 |

GE-3.0 Inverter |

GE inverter-3000

watts, 240 Vac, 60Hz (Standard 10 Year Warranty) |

|

|

|

| 0 |

0 |

GE-3.3 Inverter |

GE

inverter-3300 watts, 240 Vac, 60Hz (Standard 10 Year Warranty) |

|

|

|

| 0 |

0 |

GE-3.8 Inverter |

GE inverter-3800

watts, 240 Vac, 60Hz (Standard 10 Year Warranty) |

|

|

|

| 8 |

8 |

GE Mod5Rac |

Kit for 5 GEPV-200

Modules, 2 - 204" Rails, 8 Mid-clamps, 4 End clamps, 8 L-feet |

|

|

| 7 |

7 |

GE Splice-Clip |

Splice kit (2 splice bars and mid

clamps) |

|

|

|

|

|

| 1 |

1 |

GEPV-M2 |

GE Energy

Meter Duel Display (Production/Consumption) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| $ 73,935.16 |

$ 78,535.39 |

Published

Price |

|

|

|

|

|

|

|

|

|

|

| $ 39,554.69 |

$ 41,820.09 |

Price Less Discount |

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

| Grid Tie- 9.8 |

Grid Tie- 10.0 |

Part |

Description |

|

|

|

|

|

|

|

|

| 49 |

50 |

GEPV-200M |

GE Energy 200 Watt Photovoltaic Module, Silver Frame, White

Back Sheet, 25 Year Warranty |

| 1 |

0 |

GE-2.5 Inverter |

GE

inverter-2500 watts, 240 Vac, 60Hz (Standard 10 Year Warranty) |

|

|

|

| 2 |

3 |

GE-3.0 Inverter |

GE inverter-3000

watts, 240 Vac, 60Hz (Standard 10 Year Warranty) |

|

|

|

| 0 |

0 |

GE-3.3 Inverter |

GE

inverter-3300 watts, 240 Vac, 60Hz (Standard 10 Year Warranty) |

|

|

|

| 0 |

0 |

GE-3.8 Inverter |

GE inverter-3800

watts, 240 Vac, 60Hz (Standard 10 Year Warranty) |

|

|

|

| 10 |

10 |

GE Mod5Rac |

Kit for 5 GEPV-200

Modules, 2 - 204" Rails, 8 Mid-clamps, 4 End clamps, 8 L-feet |

|

|

| 9 |

9 |

GE Splice-Clip |

Splice kit (2 splice bars and mid

clamps) |

|

|

|

|

|

| 1 |

1 |

GEPV-M2 |

GE Energy

Meter Duel Display (Production/Consumption) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$ 100,589.47 |

$ 102,529.70 |

Published

Price |

|

|

|

|

|

|

|

|

|

|

| $ 52,808.70 |

$ 53,827.20 |

Price Less Discount |

|

|

|

|

|

|

|

|

|

|

|

|

| SKU |

1.44KWKANTK |

| Product

Title |

1.44KWTK Kaneka Solar Prepackaged/Turnkey Grid Tie

System |

| Weight

(lbs) |

915.00 |

| Your Price |

$9800.00 |

|

| |

|

|

| SKU |

GEB1.8 |

| Product

Title |

1.8 KW GE Energy Brilliance Prepackaged/Turnkey Grid Tie

System |

| Weight

(lbs) |

550.00 |

| Your Price |

$11490.00 |

|

| |

|

|

| SKU |

GEB2.6 |

| Product

Title |

2.6 KW GE Energy Brilliance Prepackaged/Turnkey Grid Tie

System |

| Weight

(lbs) |

667.00 |

| Your Price |

$15576.00 |

| Qty

1 | |

|

|

| SKU |

GEB3.0 |

| Product

Title |

3.0 KW GE Energy Brilliance Prepackaged/Turnkey Grid Tie

System |

| Weight

(lbs) |

745.00 |

| Your Price |

$17332.00 |

| Qty

1 | |

|

|

| SKU |

3.0KWKANTK Kaneka Solar Prepackaged/Turnkey Grid Tie

System |

| Product

Title |

3.0 KW Kaneka Solar Prepackaged/Turnkey Grid Tie

System |

| Weight

(lbs) |

1725.00 |

| Your Price |

$16889.00 |

| Qty

1 | |

|

|

| SKU |

GEB3.6 |

| Product

Title |

3.6 KW GE Energy Brilliance Prepackaged/Turnkey Grid Tie

System |

| Weight

(lbs) |

823.00 |

| Your Price |

$21050.00 |

| Qty

1 | |

|

|

| SKU |

GEB4.0 |

| Product

Title |

4.0 KW GE Energy Brilliance Prepackaged/Turnkey Grid Tie

System |

| Weight

(lbs) |

901.00 |

| Your Price |

$22538.74 |

| Qty

1 | |

|

|

| SKU |

GEB4.6 |

| Product

Title |

4.6 KW GE Energy Brilliance Prepackaged/Turnkey Grid Tie

System |

| Weight

(lbs) |

1019.00 |

| Your Price |

$27116.56 |

| | |

|

|

| SKU |

GEB4.8 |

| Product

Title |

4.8 KW GE Energy Brilliance Prepackaged/Turnkey Grid Tie

System |

| Weight

(lbs) |

1097.00 |

| Your Price |

$28064.99 |

| Qty

1 | |

Changing System

Parameters

If desired, the

system parameters may be changed from the default values.

| DC Rating (0.5 to

1000 kW) |

|

The size of the PV system is the nameplate DC power rating. This is

determined by summing the PV module powers listed on the nameplates on the

backsides of the PV modules in units of watts and then dividing by 1000 to

convert to kilowatts (kW). The PV module power ratings are for Standard

Test Conditions (STC) of 1000 W/m2 solar

irradiance and 25oC PV module temperature.

The default PV system size is 4 kW. This corresponds to a PV array area of

approximately 35 m2 (377 ft2).

Caution: To achieve proper results, the DC rating input must be the

nameplate DC power rating as described above, and not based on other

rating conditions, such as PVUSA Test Conditions (PTC). PTC are defined as

1000 W/m2 plane-of-array irradiance,

20oC ambient temperature, and 1 m/s wind

speed. PTC differs from standard test conditions (STC) in that its test

conditions of ambient temperature and wind speed will result in a PV

module temperature of about 50oC, instead

of the 25oC for STC. Consequently, for

crystalline silicon PV systems with a power degradation due to temperature

of -0.5% per degree C, the PV module PTC power rating is about 88% of the

PV module nameplate rating. If a user incorrectly uses a DC rating based

on PTC power ratings, the energy production calculated by PVWATTS will be

reduced by about 12% from the proper calculation. In essence, the effects

of temperature will have been erroneously compensated for twice, first

with the use of the PTC rating, and again as PVWATTS performs hour-by-hour

calculations of PV module temperatures and applies temperature corrections

from STC to the hourly PV energy values.

|

| DC to AC Derate

Factor |

| |

PVWATTS multiplies the nameplate DC power rating

by an overall DC to AC derate factor to determine the AC power rating at

STC. The overall DC to AC derate factor accounts for losses from the DC

nameplate power rating and is the mathematical product of the derate

factors for the components of the PV system. A list of the default

component derate factors used by PVWATTS and the ranges that might be

encountered in practice are listed in the table.

Derate Factors for AC Power Rating at

STC

| Component Derate

Factors |

PVWATTS

Default |

Range |

| PV module nameplate DC

rating |

0.95 |

0.80 - 1.05 |

| Inverter and Transformer |

0.92 |

0.88 - 0.96 |

| Mismatch |

0.98 |

0.97 - 0.995 |

| Diodes and connections |

0.995 |

0.99 - 0.997 |

| DC wiring |

0.98 |

0.97 - 0.99 |

| AC wiring |

0.99 |

0.98 - 0.993 |

| Soiling |

0.95 |

0.30 - 0.995 |

| System availabilty |

0.98 |

0.00 - 0.995 |

| Shading |

1.00 |

0.00 - 1.00 |

| Sun-tracking |

1.00 |

0.95 - 1.00 |

| Age |

1.00 |

0.70 - 1.00 |

|

| Overall DC-to-AC derate

factor |

0.77 |

|

The overall DC to AC derate factor is calculated by

multiplying the component derate factors.

For the PVWATTS default values:

Overall DC to AC derate factor

= 0.95 x 0.92 x 0.98 x 0.995 x 0.98 x 0.99 x 0.95 x

0.98 x 1.00 x 1.00 x 1.00

= 0.77

The value of 0.77 means that the AC power rating at STC is 77% of

the nameplate DC power rating. In most cases, the overall default value of

0.77 will provide a reasonable estimate for modeling the energy

production. However, if so warranted, users have two options to change the

overall DC to AC derate factor. The first option is to enter in the text

box a new overall DC to AC derate factor. The second option is to click

the Calculate Derate Factor button which provides the user

with the opportunity to change any of the component derate factors in the

table and then PVWATTS calculates a new overall DC to AC derate factor.

Descriptions of the component derate factors are described in the

following paragraphs.

The derate factor for the PV module nameplate DC rating accounts for

the accuracy of the manufacturer's nameplate rating. Field measurements of

a representative sample of PV modules may show that the PV module powers

are different than the nameplate rating or that they experienced

light-induced degradation upon exposure (even crystalline silicon PV

modules typically lose 2% of their initial power before power stabilizes

after the first few hours of exposure to sunlight). A derate factor of

0.95 represents that testing yielded power measurements at STC that were

5% less than the manufacturer's nameplate rating.

The derate factor for the inverter and transformer is their combined

efficiency in converting DC power to AC power. A list of inverter

efficiencies by manufacturer is at http://www.consumerenergycenter.org/cgi-bin/eligible_inverters.cgi.

These inverter efficiencies include transformer related losses when a

transformer is used or required by the manufacturer.

The derate factor for PV module mismatch accounts for manufacturing

tolerances that yield PV modules with slightly different current-voltage

characteristics. Consequently, when connected together electrically they

do not operate at their respective peak efficiencies. The default value of

0.98 represents a loss of 2% due to mismatch.

The derate factor for diodes and connections accounts for losses from

voltage drops across diodes used to block the reverse flow of current and

from resistive losses in electrical connections.

The derate factor for DC wiring accounts for resistive losses in the

wiring between modules and the wiring connecting the PV array to the

inverter.

The derate factor for AC wiring accounts for resistive losses in the

wiring between the inverter and the connection to the local utility

service.

The derate factor for soiling accounts for dirt, snow, or other foreign

matter on the front surface of the PV module that reduces the amount of

solar radiation reaching the solar cells of the PV module. Dirt

accumulation on the PV module surface is location and weather dependent,

with greater soiling losses (up to 25% for some California locations) for

high-trafffic, high-pollution areas with infrequent rain. For northern

locations in winter, snow will reduce the amount of energy produced, with

the severity of the reduction a function of the amount of snow received

and how long it remains on the PV modules. Snow remains the longest when

sub-freezing temperatures prevail, small PV array tilt angles prevent snow

from sliding off, the PV array is closely integrated into the roof, and

the roof or other structure in the vicinity facilitates snow drifting onto

the PV modules. For a roof-mounted PV system in Minnesota with a tilt

angle of 23o, snow was observed to reduce

the energy production during the winter by 70%; a nearby roof-mounted PV

system with a tilt angle of 40o experienced

a 40% reduction.

The derate factor for system availability accounts for times when the

system is off due to maintenance and inverter and utility outages. The

default value of 0.98 represents the system being off for 2% of the year.

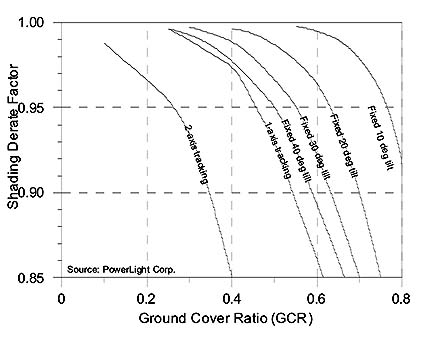

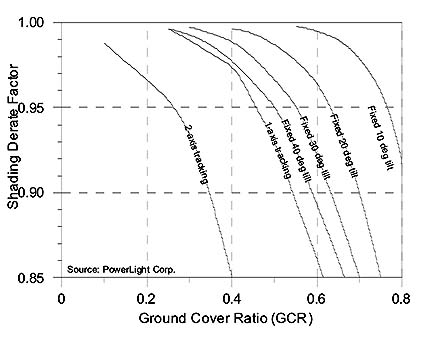

The derate factor for shading accounts for situations when PV modules

are shaded by nearby buildings, objects, or other PV modules and array

structure. For the default value of 1.00, PVWATTS assumes the PV modules

are not shaded. Tools such as Solar Pathfinder may be used to determine a

derate factor for shading by buildings and objects. For PV arrays

consisting of multiple rows of PV modules and array structure, the shading

derate factor should be changed to account for losses occurring when one

row shades an adjacent row. The figure below shows the shading derate

factor as a function of the type of PV array (fixed or tracking); the

Ground Cover Ratio (GCR), defined as the ratio of the PV array area to the

total ground area; and the tilt angle for fixed PV arrays. As shown in the

figure, spacing the rows further apart (smaller GCR) corresponds to a

larger derate factor (smaller shading loss). For fixed PV arrays, if the

tilt angle is decreased the rows may be spaced closer together (larger

GCR) to achieve the same shading derate factor. For the same value of

shading derate factor, land area requirements are greatest for 2-axis

tracking, as indicated by its relatively low GCR values when compared with

those for fixed or 1-axis tracking. If you know the GCR value for your PV

array, the figure may be used to estimate the appropriate shading derate

factor. Industry practice is to optimize the use of space by configuring

the PV system for a GCR corresponding to a shading derate factor of 0.975

(2.5% loss).

Shading Derate Factor for Multiple-Row PV Arrays

as a

Function of PV Array Type and Ground Cover Ratio

The derate factor for sun-tracking accounts for losses for one- and

two-axis tracking systems when the tracking mechanisms do not keep the PV

arrays at the optimum orientation with respect to the sun's position. For

the default value of 1.00, PVWATTS assumes that the PV arrays of tracking

systems are always positioned at their optimum orientation and performance

is not adversely affected.

The derate factor for age accounts for losses in performance over time

due primarily to weathering of the PV modules. The loss in performance is

typically 1% per year. For the default value of 1.00, PVWATTS assumes that

the PV system is in its 1st year of operation. For the 11th year of

operation, a derate factor of 0.90 would be appropriate.

Because the PVWATTS overall DC to AC derate factor is determined for

STC, a component derate factor for temperature is not part of its

determination. Power corrections for PV module operating temperature are

performed for each hour of the year as PVWATTS reads the meteorological

data for the location and computes the performance. A power correction of

-0.5% per oC for crystalline silicon PV

modules is used.

|

|

| Fixed or tracking

array |

|

The PV array may either be fixed,

sun-tracking with one axis of rotation, or sun-tracking with two axes of

rotation. The default value is a fixed PV array. |

|

|

|

| PV array tilt angle (0° to

90°) |

|

For a fixed PV array, the tilt angle is the angle from horizontal of

the inclination of the PV array (0° = horizontal, 90° = vertical). For a

sun-tracking PV array with one axis of rotation, the tilt angle is the

angle from horizontal of the inclination of the tracker axis. The tilt

angle is not applicable for sun-tracking PV arrays with two axes of

rotation.

The default value is a tilt angle equal to the station's latitude. This

normally maximizes annual energy production. Increasing the tilt angle

favors energy production in the winter, while decreasing the tilt angle

favors energy production in the summer.

For roof-mounted PV arrays, the table below gives tilt angles for

various roof pitches (ratio of vertical rise to horizontal run).

| Roof Pitch |

Tilt Angle (°) |

| 4/12 |

18.4 |

| 5/12 |

22.6 |

| 6/12 |

26.6 |

| 7/12 |

30.3 |

| 8/12 |

33.7 |

| 9/12 |

36.9 |

| 10/12 |

39.8 |

| 11/12 |

42.5 |

| 12/12 |

45.0 |

|

|

|

| PV array azimuth

angle (0° to 360°) |

|

For a fixed PV array, the azimuth angle is the angle clockwise from

true north of the direction that the PV array faces. For a sun-tracking PV

array with one axis of rotation, the azimuth angle is the angle clockwise

from true north of the direction of the axis of rotation. The azimuth

angle is not applicable for sun-tracking PV arrays with two axes of

rotation.

The default value is an azimuth angle of 180° (south-facing) for

locations in the northern hemisphere, and 0° (north-facing) for locations

in the southern hemisphere. This normally maximizes energy production. For

the northern hemisphere, increasing the azimuth angle favors afternoon

energy production, while decreasing the azimuth angle favors morning

energy production. The opposite is true for the southern hemisphere.

The table below provides azimuth angles for various headings.

| Heading |

Azimuth Angle (°) |

| N |

0 or 360 |

| NE |

45 |

| E |

90 |

| SE |

135 |

| S |

180 |

| SW |

225 |

| W |

270 |

| NW |

315 |

|

|

|

| Electricity cost |

| Version 1: For the U.S. and its Territories, the

default value is the average 2004 residential electric rate for the state

where the station is located. Source: Energy Information Administration.

For locations in regions outside the U.S., the default value is the

average 2004 or 2005 residential electric rate for the country where the

station is located. Sources: IEA Electricity Information 2005; IEA Energy

Prices & Taxes, 4th Quarter 2005; and Eurostat Gas and Electricity

Market Statistics 2005. For some countries, no electric cost information

is available and the default values are set to zero. For these countries,

the user should enter a value based on their knowledge. Electric costs are

presented in the country's currency. To convert results to another

currency, the user may go to http://www.oanda.com/converter/classic.

Version 2: Default value is the average 2004 residential electric rate

for the cell chosen by the user. Note that some areas are not covered by

any utility provider. For these areas the electric rate for the nearest

utlity service area is used. Source: Resource Data International.

|

|

Make This WebPage instantly

available in other languages

|

A high performance rechargeable

NiZn battery offers a viable alternative to hazardous NiCd

cells

That is the headline of an article that claimed

that French and Spanish partners in EUREKA project NITIN SCOOTER made the

breakthrough that will finally make nickel zinc (NiZn) batteries economically

viable. Tests conducted in-house and by independent testing centers,

including the R&D Center of Electricite de France, demonstrate that their

NiZn batteries meet commercial requirements in terms of high cycle life, high

specific energy and power, and low cost. The partners in this EUREKA

project have overcome this problem and can now produce a safe alternative to

NiCd that can be used for over 1000 charging cycles.

That is the headline of an article that claimed

that French and Spanish partners in EUREKA project NITIN SCOOTER made the

breakthrough that will finally make nickel zinc (NiZn) batteries economically

viable. Tests conducted in-house and by independent testing centers,

including the R&D Center of Electricite de France, demonstrate that their

NiZn batteries meet commercial requirements in terms of high cycle life, high

specific energy and power, and low cost. The partners in this EUREKA

project have overcome this problem and can now produce a safe alternative to

NiCd that can be used for over 1000 charging cycles.

The battery was developed while researching a new rechargeable battery for

electric scooters. The resultant battery is environmentally friendly,

inexpensive and performs well, providing energy for large and small applications

requiring a rechargeable battery. The project partners have now created

successful prototypes and are looking for additional partners to take advantage

of the potentially huge market for the new batteries, either as the power supply

for a scooter or as a more general replacement for hazardous NiCd cells.

NITIN SCOOTER made use of a copper foam developed by S.C.P.S. in EUREKA

project E! 2179 3D STRUCTURES. By adding fine particles of a new conductive

ceramic from Spanish partner, SHS Ceramicas, the consortium succeeded in

stabilizing the electrode, preventing the damaging formation of zinc compounds

that caused loss of conductivity and short circuits.

According to the S.C.P.S. web

site, the answer to traditional zinc anode troubles has been found through

the definition of a new zinc electrode which combines three key-components

- a conductive collector network, constituted by a

specific "3D" structure (a copper foam), in which is pasted a plasticized

active mass

- particles of conductive ceramics, creating a secondary

conductive "micro" network in the active mass

- specific co-additives, linked with the ceramic

particles, in charge of increasing zincate retention in the anode

The direct cost of this battery is about 33% less than the NiCd battery

and gives a 40% greater power density. The batteries are available in

capacities up to about 100 Ah.

I hadn't heard of this battery

chemistry before, (shame on me), but it sounds like it has a place in the wold

of commercial, environmentally free battery

chemistry's.

|

Make This WebPage instantly

available in other languages

|

Information provided in this site is

deemed reliable but and should be independently verified.

PROMOTING CONSCIOUSNESS ON THE

INTERNET

trujillo2001@yahoo.com

trujillo2001@yahoo.com

WebMaster

WebMaster

Major redesign

and new functionality still under heavy development,

it's a huge undertake

to redesign a large

web-site and re-link and re-structure it, thanks for your patience.

That is the headline of an article that claimed

that French and Spanish partners in EUREKA project NITIN SCOOTER made the

breakthrough that will finally make nickel zinc (NiZn) batteries economically

viable. Tests conducted in-house and by independent testing centers,

including the R&D Center of Electricite de France, demonstrate that their

NiZn batteries meet commercial requirements in terms of high cycle life, high

specific energy and power, and low cost. The partners in this EUREKA

project have overcome this problem and can now produce a safe alternative to

NiCd that can be used for over 1000 charging cycles.

That is the headline of an article that claimed

that French and Spanish partners in EUREKA project NITIN SCOOTER made the

breakthrough that will finally make nickel zinc (NiZn) batteries economically

viable. Tests conducted in-house and by independent testing centers,

including the R&D Center of Electricite de France, demonstrate that their

NiZn batteries meet commercial requirements in terms of high cycle life, high

specific energy and power, and low cost. The partners in this EUREKA

project have overcome this problem and can now produce a safe alternative to

NiCd that can be used for over 1000 charging cycles.

I m p o r t a n t S

t u f f

I m p o r t a n t S

t u f f